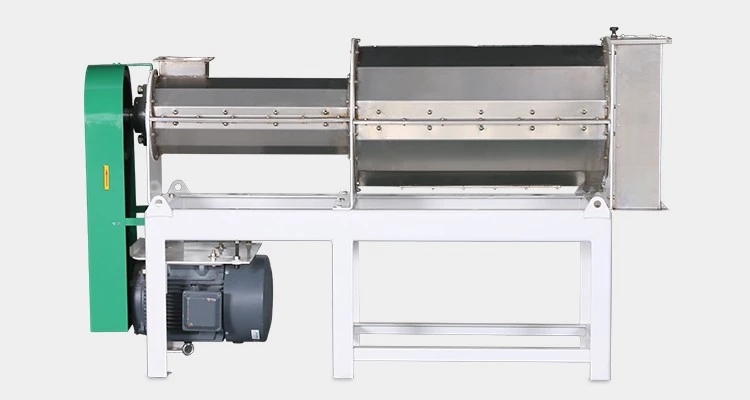

TSYZ Wheat Pressure Dampener

Brief Introduction:

Flour mill equipment-TSYZ Series pressure dampener plays an important role in wheat moisture regulation during the process of wheat cleaning in flour mills.

Product Detail

Product Tags

Product video

Product Description

TSYZ Wheat Pressure Dampener

Flour mill equipment-TSYZ Series pressure dampener plays an important role in wheat moisture regulation during the process of wheat cleaning in flour mills. It can stabilize the wheat dampening volume and make the wheat grain water content evenly to improve the grinding performance, enhance the bran toughness, reduce the endosperm strength, lower the cohesion of the bran and endosperm, and enhance the efficiency of grinding and screening, so that it’s helpful to improve the powder yield and flour quality.

As a piece of wheat intensive dampening equipment, our intensive dampener has a wide processing capacity range, from 8t/h to 25t/h, and the water addition ratio could reach 4%. The water dampening performance is even and stable, and the wheat breakage rate is quite low.

The operation, repairing and maintenance are quite convenient. So it is an excellent intensive dampening machine for the flour mill.

Working Principle

The pressure dampener machine is divided into two parts, the first half transmit the wheat by rotary blades to make the wheat surface full of water. The latter part of the blades make pressure operation to the wheat to destruct the moisture tension of wheat surface, which can increase water permeability. At the same time, when the blade stirred wheat, wheat will begin strong rotation movement during the propulsion process which will cause the wheat get disorderly stirring, so that the wheat granules dampening evenly. In addition, when wheat is stirred by blades, the wheat surface is slightly wiped away, which cleans the wheat and improves the wheat quality.

Features

Feature

1. The acclivitous transferring design of the intensive dampener ensures the water’s thoroughly blending with the grain, in favor of further dampening in the grain bins.

2. A water supply control valve is available on the inlet, ensuring the water to be shut off when there is no grain flow.

3. Low power supply is required.

4. Excellent sanitary processing can be guaranteed.

5. The top cover can be removed easily for the maintenance of intensive dampener.

6. All parts in contact with the product being processed are of stainless steel, ensuring the sanitation of the material.

The flat engine body solved the traditional water leakage problem

Separated dampening and mixing make the mixing of the material more thorough and uniform.

The adjustable material discharge can control the mixing time so that the dampening will be more accurate.

Rotor will make dynamic balance before installation so that the equipment will running smoothly.

The contact part with the material is stainless steel.

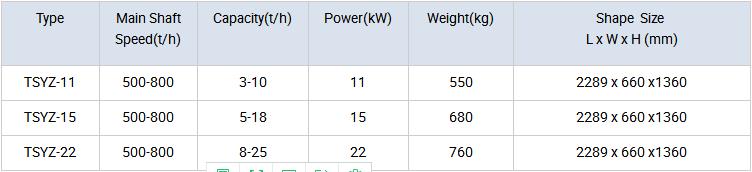

Technical Parameter List:

Packing & Delivery