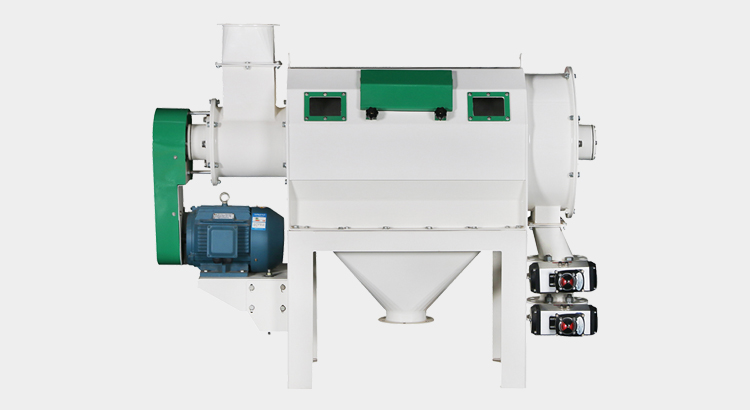

Rotary Sifter

Brief Introduction:

This type of drum sieve can be used in cleaning section in flour mill for organic offal classification.

The machine is also successfully equipped in flour silo to remove the insects, insect eggs or other choked agglomerates in the flour bin before packed.

Applied in feed mill, corn mill or other grain process plant, it can remove the block impurity, ropes or scraps in the grain, to ensure the smooth running of the equipments for the latter section and avoid accident or parts broken.

Product Detail

Product Tags

Product video

Product Description

Rotary Flour Sifter for flour mills

.jpg)

.jpg)

Principle:

The machine is mainly composed of feeding unit, driving unit and sifting unit.

Two types are available: single drum or twin drums. One motor and driving system is designed for both single type and twin type.

The materials flow into the sifting unit through the feeding unit, where the materials are divided into two streams equally by a butterfly valve. The materials are sifted in the drum sieves and pushed to the end by the strikers and brushes. The main materials go through the sieve and fall down to the outlet while the over tails are send to another outlet at the end of the machine.

Features:

- Advanced design and excellent fabricating with simple structure.

- High capacity with excellent separating efficiency.

- Low power requirement.

- Convenient for adjusting the clearance between rotor and sieve drum.

- Sieves mesh is selectable to meet various requirements for different materials and capacity.

Technical Parameter List:

| Type | Diameter(cm) | Length(cm) | Rotary Speed(r/min) | Capacity(t/h) | Aspiration Volume(m³/min) | Power(kw) | Weight(kg) | Shape SizeLxWxH(mm) | ||

| Ø1.5mm | Ø2.5mm | Ø3.0mm | ||||||||

| FSFD40/90 | 40 | 90 | 560-600 | 10-15 | 20-25 | 25-30 | 8-12 | 5.5 | 410 | 1710x630x1650 |

| FSFD40/90×2 | 40 | 180 | 20-30 | 40-50 | 50-60 | 12-16 | 11 | 666 | 1710x1160x1650 | |

Packing & Delivery

>

>