Plansifter

Brief Introduction:

As a premium flour sifting machine, the plansiftert is suitable for the flour manufacturers who process wheat, rice, durum wheat, rye, oat, corn, buckwheat, and so on.

Product Detail

Product Tags

Product video

| Type | Sections (unit) |

Sieve Height (mm) | Sieve Frame Height (no top sieve frame) (mm) |

Min Height of the Installation (mm) |

Power (kW) |

Rotary Diameter (mm) |

Main Shaft Speed (r/min) |

Sifting Area (m2) |

Weight (kg) |

||||||||

| 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | ||

| FSFG4×16 | 4 | 1800 | 1720 | 2800 | 3 | 3 | 64±2 | 245 | 21.1 | 29.1 | 2550 | 2900 | |||||

| FSFG6×16 | 6 | 1800 | 1720 | 2800 | 4 | 5.5 | 31.7 | 43.7 | 2800 | 3150 | |||||||

| FSFG8×16 | 8 | 1800 | 1720 | 2800 | 5.5 | 7.5 | 42.2 | 58.2 | 3200 | 3500 | |||||||

| FSFG4×24 | 4 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 3 | 5.5 | 31.7 | 43.7 | 2900 | 3700 | ||||

| FSFG6×24 | 6 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 4 | 7.5 | 47.5 | 65.5 | 3550 | 4550 | ||||

| FSFG8×24 | 8 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 7.5 | 11 | 63.4 | 87.4 | 4700 | 5300 | ||||

| FSFG4×28 | 4 | 2470 | 2180 | 3540 | 4 | 7.5 | 37 | 51 | 3350 | 3950 | |||||||

| FSFG6×28 | 6 | 2470 | 2180 | 3540 | 5.5 | 7.5 | 55.4 | 76.4 | 4100 | 4900 | |||||||

| FSFG8×28 | 8 | 2470 | 2180 | 3540 | 11 | 15 | 73.9 | 101.9 | 5200 | 6200 | |||||||

Pulverulent Materials Classification

The FSFG series plansifter is one of our core products developed on the basis of innovative ideas. It can efficiently sift and grade the granular and pulverulent materials. As a premium flour sifting machine, it is suitable for the flour manufacturers who process wheat, rice, durum wheat, rye, oat, corn, buckwheat, and so on. In practice, this type of mill sifter is mainly used for processing grinded wheat and middle material sifting, also for flour check sifting. Different sieving designs suit different sifting passages and intermediate materials.

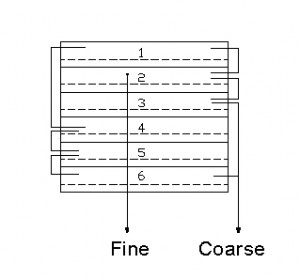

Working principle

The machine is driven by a motor which is installed inside of the main frame and counter-balanced by a counterweight. Each machine has 4, or 6, or 8 sections sieves inside. Different material flows into the different section on its own route. According to individual design for different materials, the sieve sifts different granular material to different next passage in flour mills when the whole machine is running.

Sieve frame and transmission frame

Unique design for integration of main frame and partitions into a substantial structure, and the material adopts low alloy automobile baffle.

Sieve frame column

sieve frame column adopts low alloy cold extrusion seamless shaped steel pipe, adopting mortise-tenon connection structure between the top and the bottom plate.

Sieve frame

Square wooden sieve frame, plastic coated, wear-resistant, prevent damp deformation, corners coated with metal for strong hardness, suitable size, convenient exchange. The vertical pressure lock mechanism is simple and reliable, fine work on the frame avoid powder leakage.

Sieve cleaners and tray cleaners

Sieve cleaners can prevent sieve blocking, and the tray cleaners can push the material move smoothly.

Fiber glass material suspender.

Packing & Delivery