OEM/ODM Supplier Industrial Maize Milling Machine Flour - Plansifter – Chinatown

Brief Introduction:

Product Detail

Product Tags

Related Video

Feedback (2)

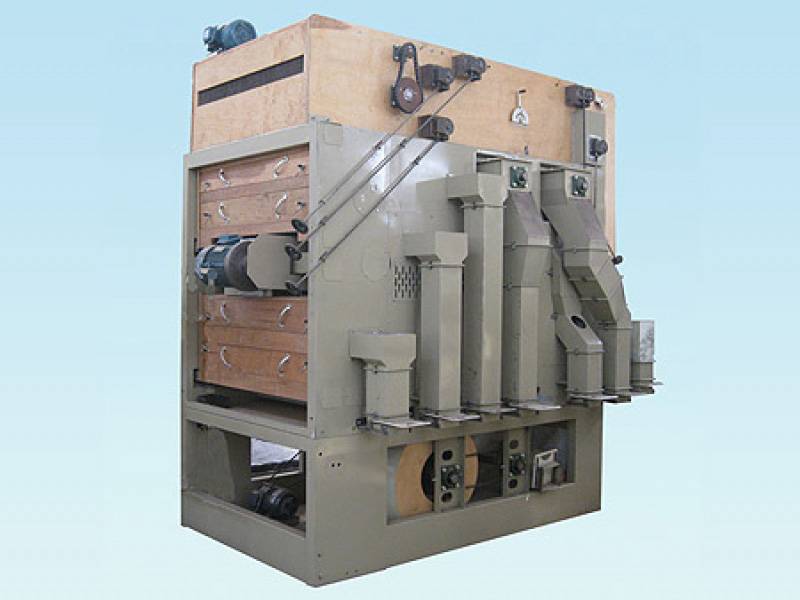

OEM/ODM Supplier Industrial Maize Milling Machine Flour - Plansifter – Chinatown Detail:

Product Description

The FSFG series plansifter is one of our core products developed on the basis of innovative ideas. It can efficiently sift and grade the granular and pulverulent materials. As a premium flour sifting machine, it is suitable for the flour manufacturers who process wheat, rice, durum wheat, rye, oat, corn, buckwheat, and so on. In practice, this type of mill sifter is mainly used for processing grinded wheat and middle material sifting, also for flour check sifting. Different sieving designs suit different sifting passages and intermediate materials.

Feature

1. The sieve frame size is available in 640×640mm and 740×740mm.

2. The plansifter’s framework is made of pressed steel plate, while the internal box walls are supplied in stainless steel. The adjustable counterweight is mounted with special SKF (Sweden) self-aligning type double row roller bearings.

3. The sieve frames are made from imported wooden whose inside and outside are both coated with plastic melamine lamination. They are demountable and interchangeable. The sieve frames are equipped with stainless steel trays. Each whole section is clamped by a metal frame and pressure micrometric screws from the top. It is easy and quick to change the sifting scheme of the plansifter when necessary.

4. The discharge outlets of this flour sifting equipment come with black plastic caps within gravity spouting scope.

5. The SEFAR sieves are adopted.

6. The NOVA sieves are also available for the plansifter. Its aluminium inner sieve can meet higher sanitation requirements, and its large bolting area and scientific structure can provide great sieving performance in limited space.

7. All the components that contact with material directly are made of stainless steel or other quality materials, ensuring the great sanitation degree.

8. Our plansifter comes with modular structure according to your needs. It is available in four-section plansifter, six-section plansifter and eight-section plansifter, so that you can make most of the existing space.

9. The inner wall and the door come with advanced thermal insulation techniques, avoiding the moisture condensation cases to a great degree.

| Type | Sections (unit) |

Sieve Height (mm) | Sieve Frame Height (no top sieve frame) (mm) |

Min Height of the Installation (mm) |

Power (kW) |

Rotary Diameter (mm) |

Main Shaft Speed (r/min) |

Sifting Area (m2) |

Weight (kg) |

||||||||

| 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | 640 | 740 | ||

| FSFG4×16 | 4 | 1800 | 1720 | 2800 | 3 | 3 | 64±2 | 245 | 21.1 | 29.1 | 2550 | 2900 | |||||

| FSFG6×16 | 6 | 1800 | 1720 | 2800 | 4 | 5.5 | 31.7 | 43.7 | 2800 | 3150 | |||||||

| FSFG8×16 | 8 | 1800 | 1720 | 2800 | 5.5 | 7.5 | 42.2 | 58.2 | 3200 | 3500 | |||||||

| FSFG4×24 | 4 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 3 | 5.5 | 31.7 | 43.7 | 2900 | 3700 | ||||

| FSFG6×24 | 6 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 4 | 7.5 | 47.5 | 65.5 | 3550 | 4550 | ||||

| FSFG8×24 | 8 | 2200 | 2300 | 1950 | 2050 | 3200 | 3300 | 7.5 | 11 | 63.4 | 87.4 | 4700 | 5300 | ||||

| FSFG4×28 | 4 | 2470 | 2180 | 3540 | 4 | 7.5 | 37 | 51 | 3350 | 3950 | |||||||

| FSFG6×28 | 6 | 2470 | 2180 | 3540 | 5.5 | 7.5 | 55.4 | 76.4 | 4100 | 4900 | |||||||

| FSFG8×28 | 8 | 2470 | 2180 | 3540 | 11 | 15 | 73.9 | 101.9 | 5200 | 6200 | |||||||

Working principle

The machine is driven by a motor which is installed inside of the main frame and counter-balanced by a counterweight. Each machine has 4, or 6, or 8 sections sieves inside. Different material flows into the different section on its own route. According to individual design for different materials, the sieve sifts different granular material to different next passage in flour mills when the whole machine is running.

Sieve frame and transmission frame

Unique design for integration of main frame and partitions into a substantial structure, and the material adopts low alloy automobile baffle.

Sieve frame column

sieve frame column adopts low alloy cold extrusion seamless shaped steel pipe, adopting mortise-tenon connection structure between the top and the bottom plate.

Sieve frame

Square wooden sieve frame, plastic coated, wear-resistant, prevent damp deformation, corners coated with metal for strong hardness, suitable size, convenient exchange. The vertical pressure lock mechanism is simple and reliable, fine work on the frame avoid powder leakage.

Sieve cleaners and tray cleaners

Sieve cleaners can prevent sieve blocking, and the tray cleaners can push the material move smoothly.

Fiber glass material suspender.

Packing & Delivery

Product detail pictures:

Related Product Guide:

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for OEM/ODM Supplier Industrial Maize Milling Machine Flour - Plansifter – Chinatown, The product will supply to all over the world, such as: El Salvador, Algeria, Las Vegas, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for yourself in China. Of course, other services, like consulting, can be offered too.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!