Manufacturer for Maida Plant Price – Chain Conveyor – Chinatown

Brief Introduction:

Product Detail

Product Tags

Related Video

Feedback (2)

Manufacturer for Maida Plant Price – Chain Conveyor – Chinatown Detail:

Our TGSS type chain conveyor is one of the most economical conveyor systems for the granular or pulverulent products handling. The processing can meet high sanitary requirements. Besides, this machine can also collect, distribute, and discharge materials. The chain is driven by gear motor and gets the material together which is fed from the inlets. Then the materials will be discharged from the outlet. The transferring distance could reach 100m, and the maximum sloping degree is 15°. In practice, this machine can be used for conveying cereal, flour, fodder, oilseed, and so on.

Our TGSS series Chain conveyor is one of the most economical solutions for handling granular and powdery materials. The head stock is made of thick steel plates, while the housing is bolted and comes with a demountable bottom. On the machine tail, there is a complete chain tensioning system which acts on the mobile pedestal by nuts. The chain is made of high strength special steel, and the plastic finned chain guide is anti-wear, and easy to demount. So it is convenient to clean the chain.

Feature

1. The machine comes with advanced design and is excellently fabricated.

2. Both sides of the chain conveyor and the bottom of the conveyor are made of 16-Mn steel plate. The slide orbit is made of polyester materials, leading to less grain break. Both of the head and tail sprockets are specially quenched and are highly anti-wear.

3. The casings (including those for drive and tail sections) are of flanged carbon steel structure and is painted with marine paint. All flanged connections are assembled with jointing strips and rubber gaskets to make the connections dustproof and watertight.

4. The chains of the chain conveyor are made of hardened carbon steel, while the drive sprockets and tail sprockets are made of hardened carbon steel. The bearings of the drive sprocket shaft and return shaft are double row spherical ball-bearings, which are dust sealed, and come with self-alignment property and have grease lubrication mechanism.

5. All drag conveyors are equipped with a flow inspection door on the head and tail section.

6. The top covers are bolted for easy removal, and are dust-tight and waterproof, making the machine suitable for outdoor installation.

7. The chain conveyor is equipped with an overflow gate and a limit switch. The overflow gate is mounted on the casing to avoid the damage of the equipment. An explosion relief panel is located at the head section of the machine.

8. The machine can work continually under full load condition, and avoid the accumulation of product and minimize the breakage risk of the grain.

9. The chains’ rails of the chain conveyor are made of carbon steel lined with wear-resistant materials, and are bolted onto the conveyor casing.

10. The enclosed machine design can effectively protect the factory from being polluted. The baffle and the material returning device can avoid the material accumulation, making sure the product is of sanitation and hygiene.

Application

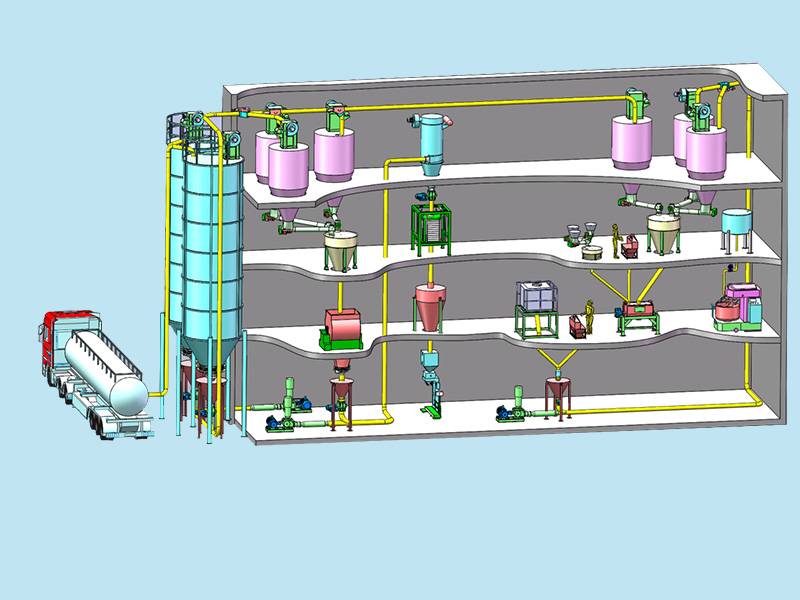

As a typical grain conveying machine, the chain conveyor is widely used in the wheat, rice, oil seed or other grain’s transferring system for its high capacity, as well as in the cleaning section of flour mill and blending section of the mill.

| Type | Capacity(m3/h) | Active Areab×H (mm) | Chain Pitch(mm) | Breaking LoadKN | Chain Speed(m./s) | Max. Transfering Inclination(°) | Max. Transfering Length(m) |

| TGSS16 | 21~56 | 160×163 | 100 | 80 | 0.3~0.8 | 15 | 100 |

| TGSS20 | 38~102 | 220×216 | 125 | 115 | |||

| TGSS25 | 64~171 | 280×284 | 125 | 200 | |||

| TGSS32 | 80~215 | 320×312 | 125 | 250 | |||

| TGSS42 | 143~382 | 420×422 | 160 | 420 | |||

| TGSS50 | 202~540 | 500×500 | 200 | 420 | |||

| TGSS63 | 316~843 | 630×620 | 200 | 450 | |||

| TGSS80 | 486~1296 | 800×750 | 250 | 450 | |||

| TGSS100 | 648~1728 | 1000×800 | 250 | 450 | |||

| TGSS120 | 972~2592 | 1200×1000 | 300 | 600 |

Packing & Delivery

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Manufacturer for Maida Plant Price – Chain Conveyor – Chinatown, The product will supply to all over the world, such as: Moldova, Rotterdam, London, We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

A good manufacturers, we have cooperated twice, good quality and good service attitude.