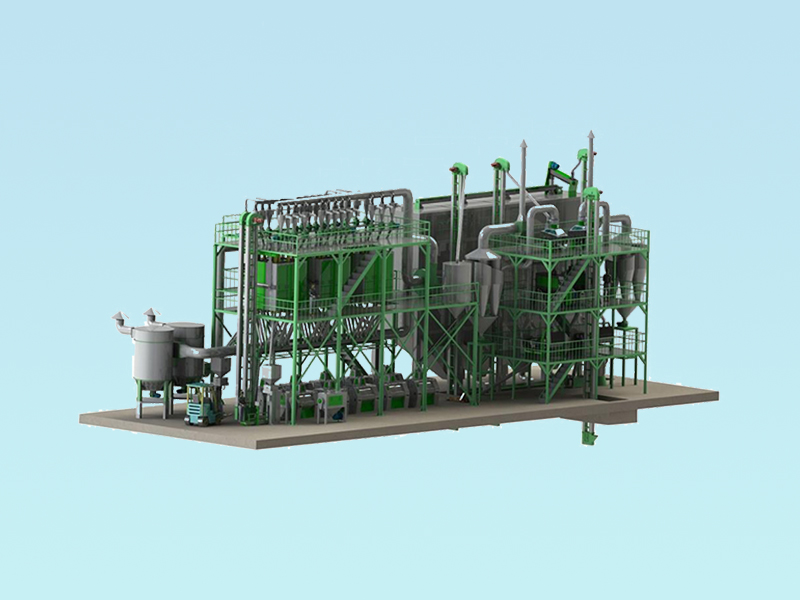

Hot-selling 150t Flour Milling – Small flour mill Plansifter – Chinatown

Brief Introduction:

Product Detail

Product Tags

Related Video

Feedback (2)

Hot-selling 150t Flour Milling – Small flour mill Plansifter – Chinatown Detail:

Product Description

Small flour mill Plansifter/single Section Plansifter

Product Application

The machine for sifting, To sift and classify material according to the particle size. Widely used in the flour mill, rice mill, feed mill, Also used in Chemical, Medical, and Other industries.

Main Features

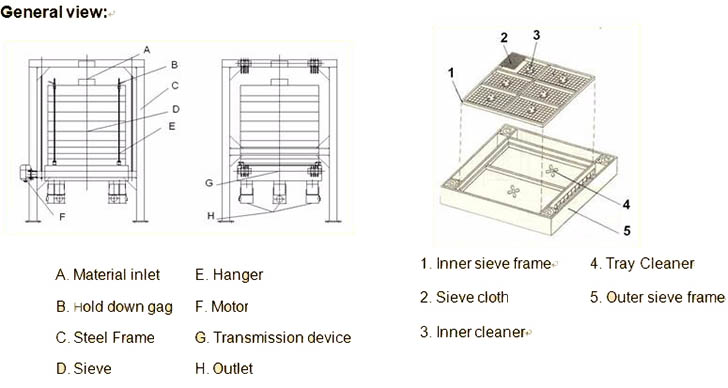

•Open and closed compartment designs are available

•6-12 Sieve frames arrangement

•Integrated vertical and horizontal compressing and locking mechanism

•Optimized rotating radius and speed

•Fiberglass rod suspension with stainless steel rope for safety

•Small footprint and flexible applications

•Laser cutting applies to sheet metal components for quality and accuracy

•Carbon dioxide gas shielded welding workmanship

•CNC machining centers ensure precise fabrication

•Powder coated parts and components for best quality and duration

•Simple structure in linear type, easy in installation and maintenance.

• Adopting advanced world famous brand components in pneumatic parts, electric parts, and operation parts.

•High-pressure double crank to control the die opening and closing.

•Running in a high automatization and intellectualization, no pollution

•Apply a linker to connect with the air conveyor, which can directly inline with the filling machine

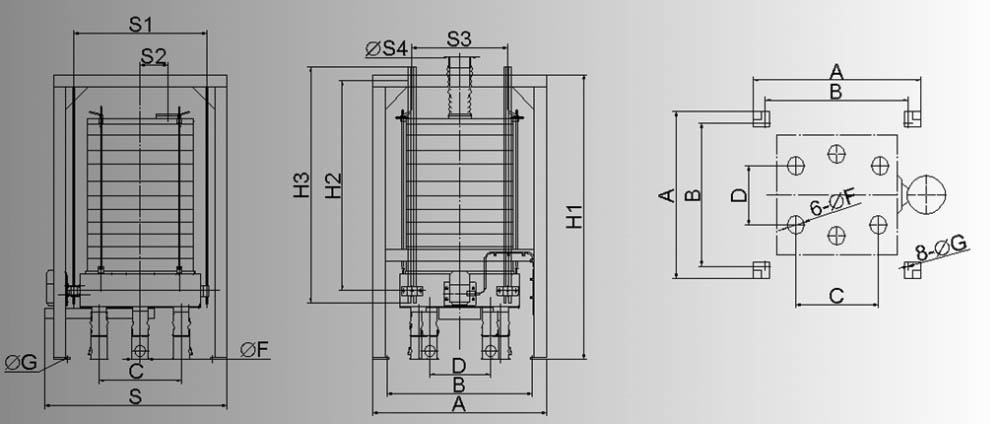

Specification

| Specification | |||||||

| Parameter | Shape Size | Power | Capacity | Weight | Rotary | Sifting Area | Diameter |

| Type | L x W x H (mm) | KW | t/h | kg | r/min | m2 | mm |

| FSFJ1x10x70 | 1250x1120x192 | 0.75 | 1.5-2 | 400 | 290 | 2.8 | 35 |

| FSFJ1x10x83 | 1390x1280x192 | 0.75 | 2-3 | 470 | 290 | 4.5 | 40 |

| FSFJ1x10x10 | 1580x1480x200 | 1.1 | 3-4 | 570 | 290 | 6.4 | 40 |

| FSFJ1x10x12 | 1620x1620x217 | 1.1 | 4-5 | 800 | 290 | 7.6 | 40 |

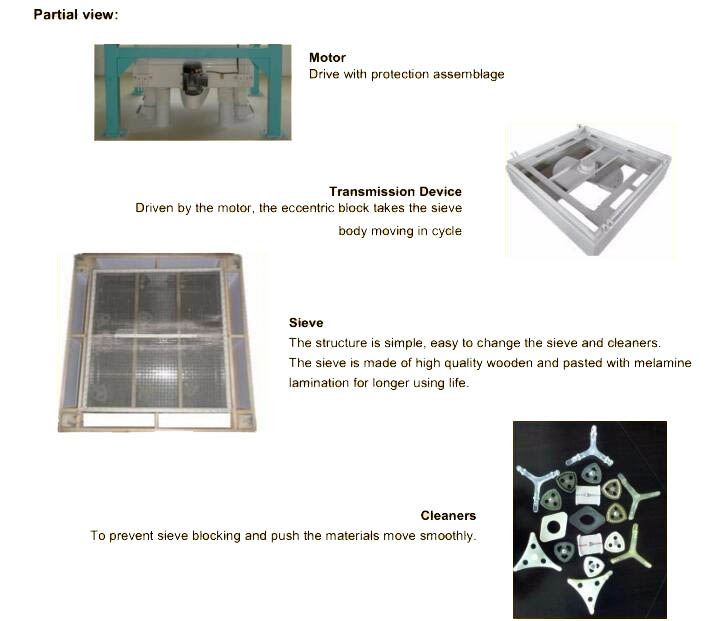

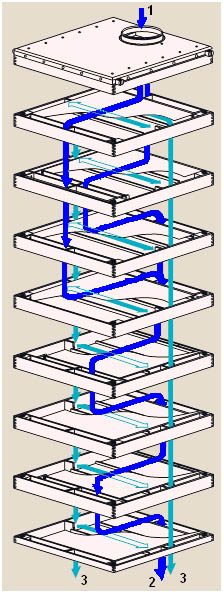

Working Principle

The Sifter (Mono-section Plansifter sieve frame) is driven by a motor installed under the main frame to do plane rotary motion through the eccentric block. The material is fed into the inlet and flows down step by step according to respective design for different materials, and in the same time it is separated to several streams according to the particle size. The material can be separated into max. four types material. The flow sheet can be designed by different requirements

Note

- The detailed cleaning and milling flow sheets could be designed following customers special requirements and the plant location.

- The wheat silos and flour and bran warehouse are excluded from the above.

- For more information or other models, please contact us.

Packing & Delivery

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for Hot-selling 150t Flour Milling – Small flour mill Plansifter – Chinatown, The product will supply to all over the world, such as: Angola, Sierra Leone, Montreal, During in 11 years, We've participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!