Good quality Flour Mill Automatic Machine - Twin-Section Plansifter – Chinatown

Brief Introduction:

Product Detail

Product Tags

Related Video

Feedback (2)

Good quality Flour Mill Automatic Machine - Twin-Section Plansifter – Chinatown Detail:

Product Description

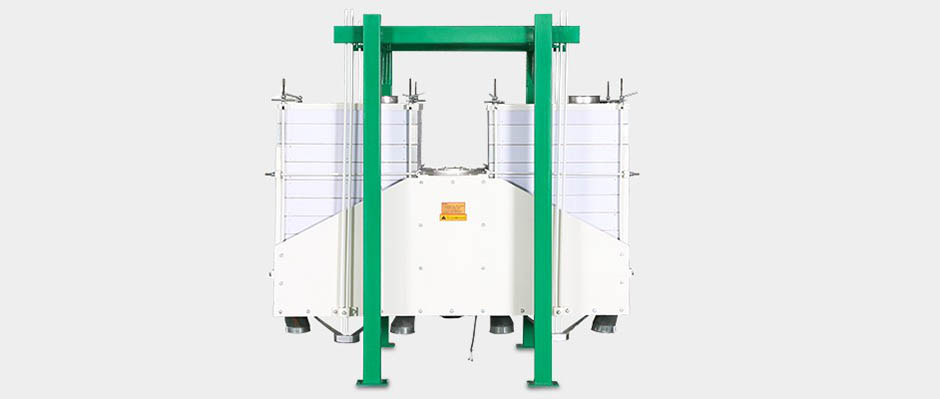

The twin-section plansifter is a kind of practical flour milling equipment. It is mainly used for the last sieving between the sifting by plansifter and the flour packing in the flour mills, as well as the classification of pulverulent materials, coarse wheat flour, and intermediate grinded materials. Currently, it has been widely adopted in modern flour mills and rice grinding mills. We can provide different sieving designs for different sifting performance and different intermediate materials.

Working principle

The Sifter is driven by a motor installed under the main frame to do plane rotary motion through the eccentric block. The material is fed into the inlet and flows down step by step according to respective design for different materials, and in the same time it is separated to several streams according to the particle size. The material can be separated into max. four types material. The flow sheet can be designed by different requirements.

Open and closed compartment designs are both available. The sieve area of closed type is larger and the sealing is better.

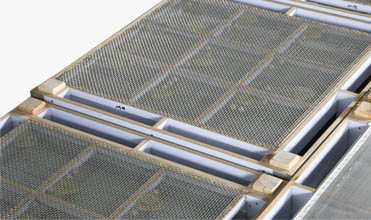

Wooden sieve frame, plastic coated to avoid damp deformation, 6-12 sieve frame arrangement per different requirement.

Integrated vertical and horizontal compressing to ensure the sieve frame tight, no displacement, no inter- leakage.

Fiberglass rod suspension for stable running and short start-up and short-down time.

Customized sieve frame arrangement per different requirement

|

Type |

Sifter Frame |

Sifting Area |

Main Shaft Speed |

Capacity |

Rotary |

Power |

Weight |

Shape Size |

|

FSFJ2×10×63 |

6-12 |

4.2 |

290 |

2-2.5 |

ø45~55 |

1.1 |

550~580 |

1680×1270×1500 |

|

FSFJ2×10×70 |

8-12 |

6.2 |

265 |

3-3.5 |

ø45~55 |

1.1 |

650~670 |

1840×1350×1760 |

|

FSFJ2×10×83 |

8-12 |

8.5 |

255 |

5-7 |

ø45~55 |

1.5 |

730~815 |

2120×1440×2120 |

|

FSFJ2×10×100 |

10-12 |

13.5 |

255 |

8~10 |

ø45~55 |

2.2 |

1200~1500 |

2530×1717×2270 |

Packing & Delivery

Product detail pictures:

Related Product Guide:

Each individual member from our large performance revenue crew values customers' needs and company communication for Good quality Flour Mill Automatic Machine - Twin-Section Plansifter – Chinatown, The product will supply to all over the world, such as: Chile, Cambodia, Bolivia, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.