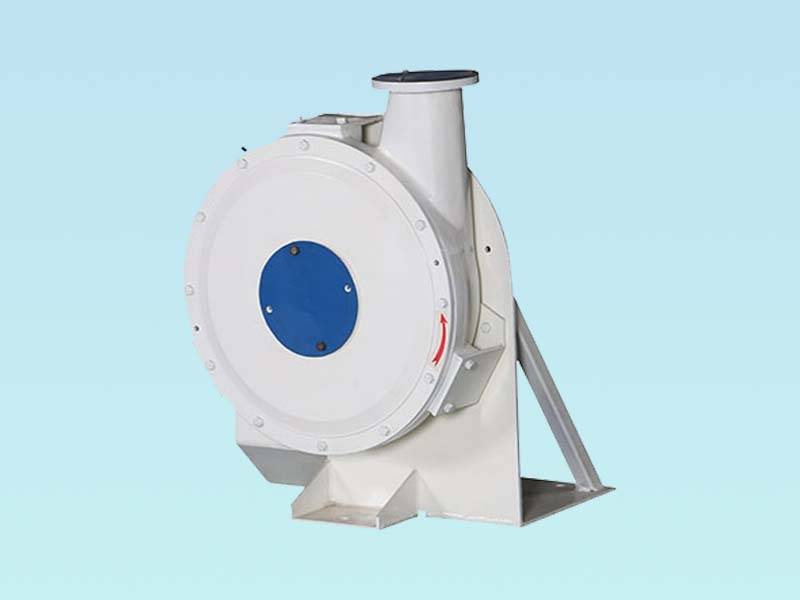

Flour Milling Equipment Insect Destroyer

Brief Introduction:

Flour milling equipment insect destroyer widely applied in modern flour mills to increase the extraction of flour and help mill.

Product Detail

Product Tags

Product video

Product Description

Our durable impact detacher is for improving the flour extraction rate in the flour milling plant. With the high-speed rotors, it can smash the endosperm flakes, especially flakes ground by smooth rollers. Thus the sieving efficiency could be enhanced to some degree. Besides, this step can also kill the bugs and inhibit the bug eggs and larva from growing, and keep the granules in a fluffy state.

Work Principle

This machine is designed for detaching endosperm particles after reduce milling by smooth rollers to increase the extraction of flour in flour mills. The circular machine comprises casting iron housing and the motor is flanged installed on the housing. A rotary pin plate is fixed on the motor axis directly. A fixed is pin plate combined with the housing. The materials are fed into the machine from the center and discharged from its outlet which is in the tangential direction. Meanwhile, intensive impact occurs between the pins fixed on the motor and the pins on the housing. b, the motoring plate and the pins on the housing c, the pins fixed on the motor and the housing Thus some endosperm sheets caused by smooth roller are released and become flour, some granular semolina is crashed to flour or falls off from bran. The rotor is dynamically balanced and painted with a transparent food lacquer to prevent rusting. The impacting pins surfaces are heat treated to ensure wear resistance.

Features Advanced design and excellent fabricating.

1. The machine comes with a dynamically balanced rotor, ensuring smooth running.

2. Welded steel housing and anti-wear components are adopted for this equipment. The excellent durability leads to limited maintenance fees.

3. The impact detacher is manufactured according to our advanced design. The advanced processing machine and techniques have guaranteed the desirable precision and product quality.

4. The impacting pins surfaces are thermally treated to achieve desirable wear resistance.

5. The round pins and square pins are optional for different passing properties and impact intensities.

6. High-quality motor is adopted for the impact detacher to ensure the machine’s stable running.

7. Small area is needed for the installation of this flour-making equipment, and two installation types are optional. It can be mounted in the gravity conveying system or incorporated in the pneumatic conveying pipeline.

8. No floating dust will be generated and the repairing and operation are both very convenient.

9. The impact detacher is available in two kinds of sizes and capacities.

10. A by-pass pipe and matching imported limit switch are installed. Thus when the machine stops, the mill system can continue to work.

11. The surface of the low carbon alloy steel pin, after treated with nitriding and carbonization techniques, has become quite anti-wear.

Application

Widely applied in modern flour mills to increase the extraction of flour and help mill. Two machine sizes for different capacities. Two installation types are optional: supported for gravity inlet, suspended when installed in the pneumatic line.

Equipment parameter

| Type | Capacity(t/h) | Rotary Speed(r/min) | Diameter(mm) | Number of Round Pin | Number of Square Pin | Power(kw) | Shape Size LxWxH (mm) |

| FSJZ43 | 1.5 | 2830 | 430 | 80 | 3 | 576×650×642 | |

| 2.5 | 2890 | 430 | 80 | 4 | |||

| 4 | 2900 | 430 | 80 | 5.5 | |||

|

FSJQ51 |

1 | 2910 | 510 | 192 | 64 | 5.5 | 576×650×642 |

| 1.7 | 2910 | 510 | 192 | 64 | 7.5 | ||

| 2.8 | 2930 | 510 | 192 | 64 | 11 | ||

| 4 | 2930 | 510 | 192 | 64 | 15 |

Packing & Delivery