Flour Mill Equipment – purifier

Brief Introduction:

Flour mill purifier widely applied in modern flour mills to produce flour with high quality. Successfully used to produce semolina flour in durum flour mills.

Product Detail

Product Tags

Product video

Product Description

Flour Mill Equipment - purifier

Our FQFD series purifier features with high capacity, high economical efficiency, high reliability and perfect design. It is suitable for purifying and classifying the grinded grain in modern flour mills for flour of soft wheat, durum wheat, and corn. In addition, it has also been successfully used for semolina flour in durum flour mills.

Features

1、Adopting vibration motor transmission structure, to achieve the ideal screening effect through vibration, blowing and screening. The screening rate and ash reduction rate is more competitive than any other machines.

2、Adopting the brusher (or rubber ball cleaners) to clean the screen surface, and the cleaning effect is good.

3、All supporting points adopt rubber spring or rubber bearing, not need lubrication to maintain. And it has the features of stable movement, vibration reduction, vibration isolation, durability and no noise.

4、Both the total air volume and each air chamber can be adjusted, which can effectively control the aspiration volume of each air chamber.

5、The vibrating system can be balanced by the synchronous vibration of the sieve body, the material separating device and the conveying trough.

6、The feeding system has reliable balance device, which can ensure the balance when the material enters the screening process.

7、Both the overtails and throughs have adjusting device, which can conveniently control the material flow direction according to the process requirements.

8、It adopts excellent design, and has the features of reasonable structure, effective dustproof measures,and low failure rate. And it is convenient to inspect, maintain and adjust.

9. This flour mill purifier comes with advanced design and excellent fabricating.

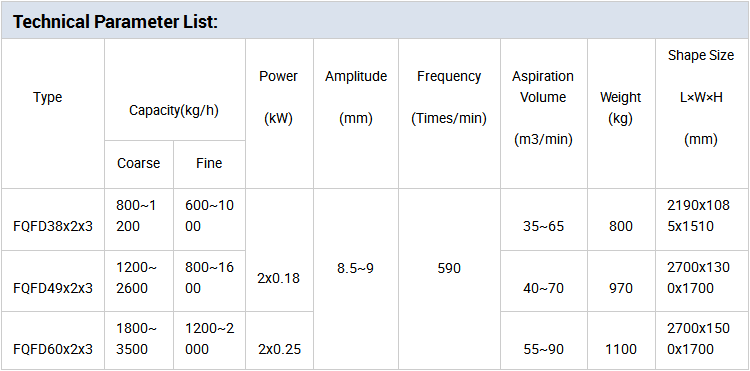

10. The sieve size could be 380mmx380mm, 490mmx490mm, or 600mmx600mm.

11. The inlets and conveying and collecting troughs are made of aluminum alloy to get more desirable durability.

12. The imported rubber spring bushes are reliable.

13. The SEFAR cloth is also imported for the equipment.

14. High quality vibration motor is adopted for the purifier.

15. The sifting area is quite large, leading to 20% higher production capacity, while the minimum installation area is required.

16. To get excellent sanitary performance during the production, we adopted high quality anticorrosive materials to avoid the product from being contaminated. Besides, the enclosed type purifier can totally meet the international sanitary standards.

17. The low maintenance vibration components and zero maintenance transmission mechanism can reduce the downtime to a very low level.

18. The air flow control is easy and accurate, ensuring the air flow is distributed in an efficient way and the energy waste is largely reduced.

The plexiglass glass cover of the discharging part can keep the negative pressure in the machine,which is much cleaner, and the purifier will have higher working efficiency.

The air volume of each part can be adjusted accurately through the plexiglass observation window.

The size of the aspiration outlet can be adjusted according to the flour purifying effect.

The sieve frame is made of aluminum alloy with light weight, which can ensure high sensitivity of the machine.

Adopting China famous motor brand: JBM or Sanyuan, and imported rubber spring.

Packing & Delivery