-

China Cheap price Flour Machine Price - Flour Blending – Chinatown

First, the different quality and different grades of flour produced in the milling room are sent to different storage bins through conveying equipment for storage. These flours are called basic flour. Before the basic powder enters the warehouse, it must go through the procedures of flour inspection, metering, magnetic separation, and insecticide. When mixing flour is needed, the basic flours of several varieties that need to be matched are discharged from the bin, mixed together according to... -

Factory source Grinding Flour Machine - Flour Blending – Chinatown

First, the different quality and different grades of flour produced in the milling room are sent to different storage bins through conveying equipment for storage. These flours are called basic flour. Before the basic powder enters the warehouse, it must go through the procedures of flour inspection, metering, magnetic separation, and insecticide. When mixing flour is needed, the basic flours of several varieties that need to be matched are discharged from the bin, mixed together according to... -

Factory Supply Small Maize Milling Machine - Flow Scale For Flour Mill – Chinatown

Product Description Flow Scale For Flour Mill Our LCS series flow scale is used for the gravity dosing system for material flow in the flour mill. It is perfectly suitable for blending various kinds of grains while keeping the flow at a certain speed. Application: The weighing device used to weigh intermediate product. Widely used in the Flour mill, Rice mill, Feed mill. Also used in Chemical, Oil, and Other industry. Features: 1. We use high performance weighting sensor so that we can ac... -

Manufacturer of Flour Machine Cost - Flour Blending – Chinatown

First, the different quality and different grades of flour produced in the milling room are sent to different storage bins through conveying equipment for storage. These flours are called basic flour. Before the basic powder enters the warehouse, it must go through the procedures of flour inspection, metering, magnetic separation, and insecticide. When mixing flour is needed, the basic flours of several varieties that need to be matched are discharged from the bin, mixed together according to... -

2020 Good Quality Small Scale Maize Milling Machine - Lower Density Materials Discharger – Chinatown

Product Description 1.It is difficult to discharge the materials from the flatbottomed silo, especially for the low density and the poor flowability materials, which are more difficult to discharge. This machine can solve the problem very well. 2.This machine is made of one wear-resistant chain and solid body with two flap spout by pneumatic. The transmission is done by the reduce motor and a special damper driving a double concentric shaft, which drive the chain with different scraper unif... -

Manufactur standard Flour Mill Machinery Milling – Electrical Roller Mill – Chinatown

Product Description Electrical Roller Mill The machine for grain grinding Widely used in Flour Mill, Corn Mill, Feed Mill and so on. Working principle After the machine start up, the rollers begin to rotate. The distance of two rollers is wider. During this period, there is no material fed into the machine from inlet. When engaging, the slower roller moves to faster roller normally, meanwhile, the feeding mechanism begins to feed material. At this time, the related parts of feeding mechan... -

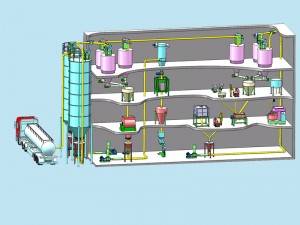

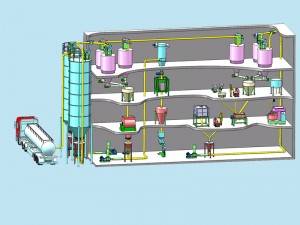

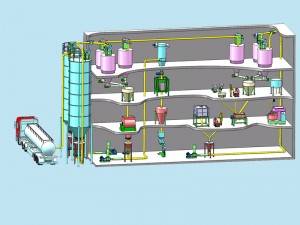

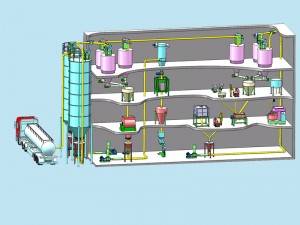

OEM/ODM China Machine Wheat Flour Milling – Big capacity wheat flour mill – Chinatown

Product Description Big capacity wheat flour mill CLEANING SECTION In the cleaning section,we adopt drying type cleaning technology.it normally includes 2 times sifting,2 times scouring,2times de-stoning,one time purifying,5 times aspiration,2 times dampening,3 times magnetic separationand so on.In the cleaning section,there are several aspiration systems which can reduce the dust spray-out from the machine and keep a good working environment.The above flow sheet which can remove most of t... -

Good Wholesale Vendors Flour Machine Cost - Flow Scale For Flour Mill – Chinatown

Product Description Flow Scale For Flour Mill Our LCS series flow scale is used for the gravity dosing system for material flow in the flour mill. It is perfectly suitable for blending various kinds of grains while keeping the flow at a certain speed. Application: The weighing device used to weigh intermediate product. Widely used in the Flour mill, Rice mill, Feed mill. Also used in Chemical, Oil, and Other industry. Features: 1. We use high performance weighting sensor so that we can ac... -

2020 China New Design Maize Processing Machine - Flow Balancer – Chinatown

Product Description Flow balancer Online batching system Flow balancer: Adopting the pressure sensor and single chip technology, it has similar working principle with Buhler, the difference is the actuator of Buhler adopts cylinder control gate, but we use the energy saving gear motor (≤40W) to control the slide gate, which not only greatly improved the wheat proportion precision and saved a lot of energy, but also not affected by temperature in winter. Flow balancer is an independent close... -

Manufacturer for Flour Plant - Flow Balancer – Chinatown

Product Description Flow balancer Online batching system Flow balancer: Adopting the pressure sensor and single chip technology, it has similar working principle with Buhler, the difference is the actuator of Buhler adopts cylinder control gate, but we use the energy saving gear motor (≤40W) to control the slide gate, which not only greatly improved the wheat proportion precision and saved a lot of energy, but also not affected by temperature in winter. Flow balancer is an independent close... -

One of Hottest for Grain Flour Mill Machine - Pneumatic Roller Mill – Chinatown

Product Description Pneumatic Roller Mill The pneumatic roller mill is an ideal grain milling machine for processing corn, wheat, durum wheat, rye, barley, buckwheat, sorghum, and malt. Widely used in Flour Mill, Corn Mill, Feed Mill, and so on. The length of the milling roller is available in 500mm, 600mm, 800mm, 1000mm, and 1250 mm. The roller mill can automatically adjust the opening degree of the door of the feeding mechanism. First-class pneumatic components are used to achieve reliabl... -

Cheapest Price Maida Mill Machine - Seed Packer – Chinatown

Product Description Our DCSG series intelligent seed packer comes with adjustable feeding speeds (low, middle, high), special auger feeding mechanism, digital frequency technique and anti-interference technique. The automatic compensation and amending functions are both available. This seed packing machine is suitable for the quantitative packing of loose and cohesionless materials (such as rice, wheat, plastic granule) in industries like food, grain, condiment, pesticide, fodder, chemicals, ...