Factory Supply Besan Mill Plant - Flour Mill Machinery Pulse Jet Filter – Chinatown

Brief Introduction:

Product Detail

Product Tags

Related Video

Feedback (2)

Factory Supply Besan Mill Plant - Flour Mill Machinery Pulse Jet Filter – Chinatown Detail:

Product Description

Flour Mill Machinery Pulse Jet Filter

.jpg)

Pulse dust collectors have desirable dust removing efficiency and are easy to be maintained. Thus far, they are widely used in the aspiration system and pneumatic conveying system.

Pulse-jet filters widely used in the Food, Grain, and Feed industries. Also used in Chemical, Medical, and other industries.

Work Principle

The pulse jet filter usually works together with a centrifugal fan. It takes in the air and adsorbs the dust in the air by its filtering cloth bag. Then the dust will be blown off by the pulse air current from the device’s top, thus the dust is collected into the pulse jet bag filter rather than entering the ambient environment of the workshop.

Features

1)Tangent air inlet design can first separate bigger dust particles to reduce the load of the filters. It also can be made square shape according to requirements.

2) High efficiency, particle < 1 um, efficiency > 95%; Particle > 1 um, efficiency > 99.5%

3) 2 or more filters can be controlled together as one unit.

4) High quality filter cloth ensures the de-dust efficiency and wear resistance.

Steel frame sleeve/ Spring frame sleeve:Made of high quality material to support sleeves.

Sleeves

Dust sleeves is a key part in the operation process of the sleeves type jet filter. With the ideal filter the sleeves has good aspiration performance and high dust removal efficiency, and has a certain acid resistance, alkali resistance and heat resistance, it also has elasticity, so the dust removal effect is good, and the dust removal rate can reach 99.99%. The material of sleeves can use anti-static, waterproof materials according to the requirements.

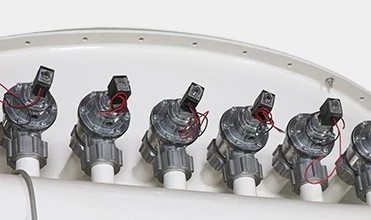

The solenoid valve can control injection sleeve, without mechanical wear and error.

Pulse controller:Easy to adjust the gap time and injection time of the injection sleeves.

The design of the inspection door made the replace of sleeves more easily. The jet filter can be made into clamshell type, and the sleeves can be optionally extracted and replaced at random without the workers entering the machine body

TBLM Type Low Pressure Jet Filter

| Type | Sleeves Length (mm) |

Air Volume (m³/h) |

Sleeves Area (m²) |

Power(kW) | Weight (kg) |

|

| Air Lock | Dust Scraper | |||||

| TBLM-26 | 1800 2000 2400 |

1032-5160 1146-5730 1380-6900 |

17.2 19.1 23 |

0.75 | 710 749 794 |

|

| TBLM-52 | 1800 2000 2400 |

2112-10560 2292-11460 2766-13830 |

35.2 38.2 46.1 |

1.1 | 1.5 | 1230 1500 1700 |

| TBLM-78 | 1800 2000 2400 |

3090-15450 3438-17190 4146-20730 |

51.5 57.3 69.1 |

1720 1800 2000 |

||

| TBLM-104 | 1800 2000 2400 |

4116-20580 4590-22950 5526-27630 |

68.6 76.5 92.1 |

2200 2500 3000 |

||

| TBLM-130 | 1800 2000 2400 |

5292-26460 5934-29670 7056-35280 |

88.2 98.9 117.6 |

2870 3000 3500 |

||

| TBLM-168 | 1800 2000 2400 |

7596-37980 5934-29670 9114-45570 |

113.9 126.6 151.9 |

1.5×2 | 2.2 | 3540 3721 3925 |

TBHM Type High Pressure Jet Filter

| Type | Sleeves Quantity (PC) |

Air Volume (m³/h) |

Sleeves Area (m²) |

Solinoid Valve Quantity (PC) |

Rising Air Pressure (MPa) |

Air Filtrating Speed (m/min) |

Sleeves Size D×L (mm) |

Resistence (Pa) |

| TBHM-24 | 24 | 3270-4360 | 18.2 | 4 | 0.4-0.6 | 3-4 | ø120×2000 | <980 |

| TBHM-36 | 36 | 4950-6600 | 27.5 | 6 | ||||

| TBHM-48 | 48 | 6520-8680 | 36.2 | 8 | ||||

| TBHM-60 | 60 | 8130-10850 | 45.2 | 10 | ||||

| TBHM-72 | 72 | 9800-13200 | 54.3 | 12 | ||||

| TBHM-84 | 84 | 11400-15200 | 63.3 | 14 | ||||

| TBHM-96 | 96 | 13000-17400 | 72.5 | 16 | ||||

| TBHM-108 | 108 | 14300-19540 | 81.4 | 18 | ||||

| TBHM-120 | 120 | 16300-21600 | 90.5 | 20 |

TCR Type Inserted High Pressure Jet Filter

| Type | Sleeves Area (m²) |

Air Voloume (m³/min) |

Power (kW) |

| TCR-4/8 | 1.24 | 223-298 | 1.1 |

| TCR-4/12 | 1.86 | 334-447 | 1.1 |

| TCR-6/8 | 1.86 | 334-447 | 1.1 |

| TCR-6/12 | 2.76 | 496-663 | 1.1 |

| TCR-9/8 | 2.8 | 504-672 | 1.5 |

| TCR-9/12 | 4.14 | 745-994 | 1.5 |

| TCR-9/16 | 5.76 | 1036-1383 | 1.5 |

| TCR-16/12 | 6.88 | 1238-1652 | 2.2 |

| TCR-16/18 | 10.24 | 1843-2458 | 2.2 |

| TCR-16/24 | 13.76 | 2476-3303 | 2.2 |

| (Rectangular Inserted High Pressure Jet Filter is also available) | |||

Packing & Delivery

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Factory Supply Besan Mill Plant - Flour Mill Machinery Pulse Jet Filter – Chinatown, The product will supply to all over the world, such as: Paraguay, Zimbabwe, India, Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.