Factory source Cost Of Setting Up A Flour Mill - Twin-Section Plansifter – Chinatown

Brief Introduction:

Product Detail

Product Tags

Related Video

Feedback (2)

Factory source Cost Of Setting Up A Flour Mill - Twin-Section Plansifter – Chinatown Detail:

Product Description

Technical Parameter List

|

Type |

Sifter Frame |

Sifting Area |

Main Shaft Speed |

Capacity |

Rotary |

Power |

Weight |

Shape Size |

|

FSFJ2×10×63 |

6-12 |

4.2 |

290 |

2-2.5 |

ø45~55 |

1.1 |

550~580 |

1680×1270×1500 |

|

FSFJ2×10×70 |

8-12 |

6.2 |

265 |

3-3.5 |

ø45~55 |

1.1 |

650~670 |

1840×1350×1760 |

|

FSFJ2×10×83 |

8-12 |

8.5 |

255 |

5-7 |

ø45~55 |

1.5 |

730~815 |

2120×1440×2120 |

|

FSFJ2×10×100 |

10-12 |

13.5 |

255 |

8~10 |

ø45~55 |

2.2 |

1200~1500 |

2530×1717×2270 |

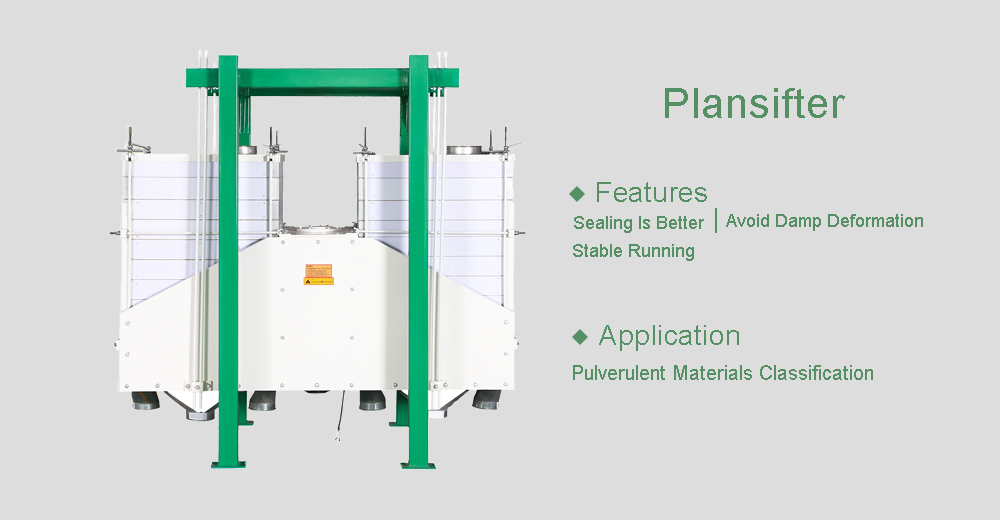

Sealing Is Better

Open and closed compartment designs are both available. The sieve area of closed type is larger and the sealing is better.

Avoid Damp Deformation

Wooden sieve frame, plastic coated to avoid damp deformation, 6-12 sieve frame arrangement per different requirement.

Stable Running

Fiberglass rod suspension for stable running and short start-up and short-down time.

Customized Sieve Frame

Customized sieve frame arrangement per different requirement.

Pulverulent Materials Classification

The twin-section plansifter is a kind of practical flour milling equipment. It is mainly used for the last sieving between the sifting by plansifter and the flour packing in the flour mills, as well as the classification of pulverulent materials, coarse wheat flour, and intermediate grinded materials. Currently, it has been widely adopted in modern flour mills and rice grinding mills. We can provide different sieving designs for different sifting performance and different intermediate materials.

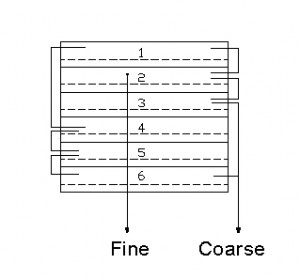

Working principle

The Sifter is driven by a motor installed under the main frame to do plane rotary motion through the eccentric block. The material is fed into the inlet and flows down step by step according to respective design for different materials, and in the same time it is separated to several streams according to the particle size. The material can be separated into max. four types material. The flow sheet can be designed by different requirements.

Our Factory

Packing & Delivery

Product detail pictures:

Related Product Guide:

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for Factory source Cost Of Setting Up A Flour Mill - Twin-Section Plansifter – Chinatown, The product will supply to all over the world, such as: Mali, Russia, Manchester, Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.