Factory Free sample Flour Mill Line – Electrical Roller Mill – Chinatown

Brief Introduction:

Product Detail

Product Tags

Related Video

Feedback (2)

Factory Free sample Flour Mill Line – Electrical Roller Mill – Chinatown Detail:

Product Description

Electrical Roller Mill

The machine for grain grinding

Widely used in Flour Mill, Corn Mill, Feed Mill and so on.

Working principle

After the machine start up, the rollers begin to rotate. The distance of two rollers is wider. During this period, there is no material fed into the machine from inlet. When engaging, the slower roller moves to faster roller normally, meanwhile, the feeding mechanism begins to feed material. At this time, the related parts of feeding mechanism and roller gap adjusting mechanism begin to move. If the distance of two rollers is equal to working roller gap, two rollers engaged and begin to grind normally. When disengaging, the slower roller leaves from faster roller, meanwhile, the feeding roller stops feeding material. The feeding mechanism makes the material flow into the grinding chamber stably and spreads the material on the roller working width uniformly. The working state of feeding mechanism is in accord with the working state of roller, feeding material or stopping material can be controlled by the feeding mechanism. The feeding mechanism can adjust the feeding rate automatically according to the volume of feeding material.

Features

1) Roller is made of centrifugal cast iron, dynamically balanced for a long working span.

2) Horizontal roller configuration and servo-feeder contribute to a perfect grinding performance.

3) Air aspiration design for the roller gap help to reduce the temperature of the grinding roller.

4) Automatic operation system makes it possible to display or modify the parameter very simply.

5) All the roller mills can be central controlled (e.g. engaged/disengaged) through PLC system and in control room center.

Technical Parameter List:

| Type | Roller Length(mm) | Roller Diameter(mm) | Feeding Motor(kw) | Weight(kg) | Shape Size LxWxH(mm) |

| MME80x25x2 | 800 | 250 | 0.37 | 2850 | 1610x1526x1955 |

| MME100x25x2 | 1000 | 250 | 0.37 | 3250 | 1810x1526x1955 |

| MME100x30x2 | 1000 | 300 | 0.37 | 3950 | 1810x1676x2005 |

| MME125x30x2 | 1250 |

300 |

0.37 | 4650 | 2060x1676x2005 |

Packing & Delivery

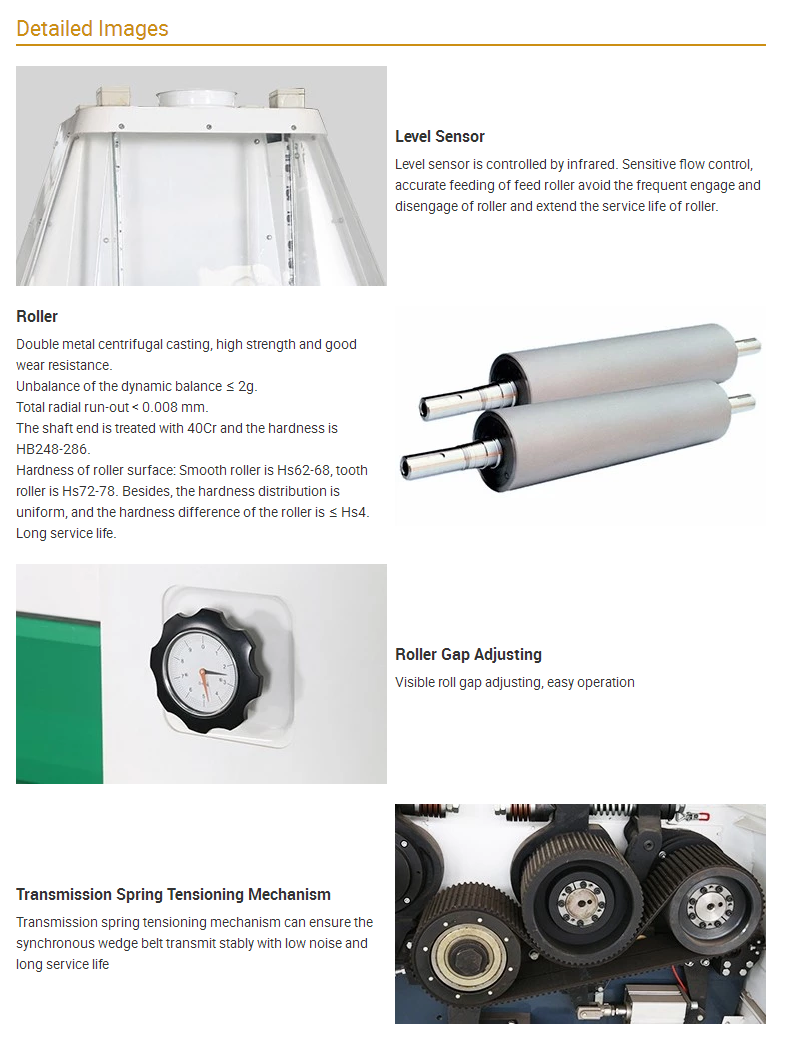

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for Factory Free sample Flour Mill Line – Electrical Roller Mill – Chinatown, The product will supply to all over the world, such as: Honduras, UK, Zambia, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.