China Factory for Industrial Maize Milling Machine - Vibro Separator – Chinatown

Brief Introduction:

Product Detail

Product Tags

Related Video

Feedback (2)

China Factory for Industrial Maize Milling Machine - Vibro Separator – Chinatown Detail:

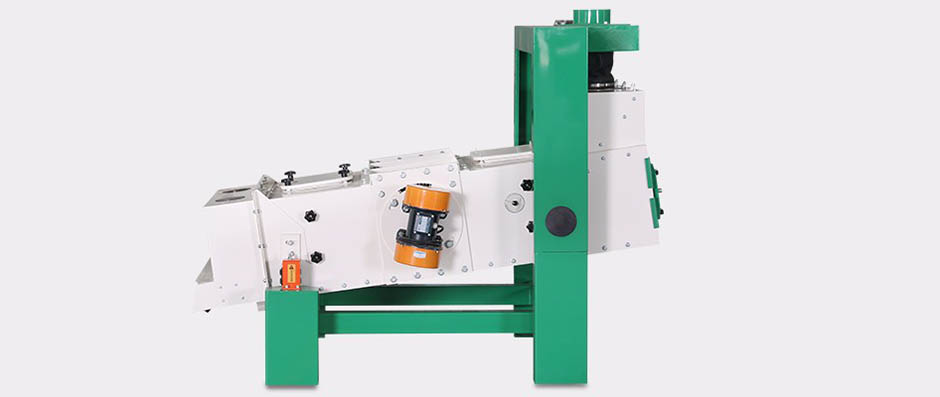

This high performance vibro separator, also named vibration screen, together with the aspiration channel or recycling aspiration system is widely used in flour mills and silos. Thus far, this kind of grain separating equipment has been successfully used in feed mills, seeds cleaning plants, oilseed cleaning plants, cocoa bean and cocoa nibs grading systems in chocolate factories, as well as in the food processing and feed manufacturing industries. It is especially suitable for grain with many impurities.

Working principle

Vibrato separator is designed with different sieve to remove the impurities according to the different length, width, thickness and weight between the grain and impurities. under the function of vibration motor, the materials on the sieve will vibrate and de-compact inordinately, so the materials will grade automatically.

Feature

1. The vibrating screen comes with simple design and low operational noise, and is easy to maintain.

2. We have expanded the coarse sieve of the high performance vibro separator to the bottom of the feeding box. Now the coarse sieve is nearly 300mm longer than that of similar products. Thus the sifting area of the coarse sieve is enhanced, and the fine mesh sieve has higher utilization rate.

3. The vibrating magnitude of the vibrating sieve is higher than many similar products. Accordingly, we have strengthened the separator’s structure. The air recycling aspirator also has higher air flow volume than that of similar products.

4. The other features include high toughness, compact structure, flexible adjustment, dustproof property, stable operation, great cleaning performance, easy relocation, and so on.

5. Two layer sieves make the machine with the best cleaning effect.

Sieve frame

Sieve plate is made of high quality steel plate, its hole size is determined by the flow process; easy to install and disassemble; sieve frame compress vertically to prevent jumping.

Ball cleaners

In the process of sieving, a good sieve surface cleaning is one of the important factors to ensure high efficiency sieving. The movement of the ball cleaners can clean the sieve plate, and the blockage rate is low.

Feed box

can be overturned or disassembled, easy to draw out and insert the sieve frame.

It is very convenient to adjust the inclination of the sieve surface: the machine frame is made by pressed steel plate, and the sieve frame is supported by height-adjustable cross arms.

The amplitude of vibration motor can be adjusted according to the material characteristics, capacities and so on.

| Type | Sieve Size (cm) |

Capacity for Wheat(t/h) | Amplitude (mm) |

Power (kW) |

Weight (kg) |

Shape Size L×W×H (mm) |

|

| Pre-Cleaning | Cleaning | ||||||

| TQLZ40×80 | 40×80 | 3-4 | 2-3 | 4~5 | 2×0.12 | 190 | 1256×870×1070 |

| TQLZ60×100 | 60×100 | 10-12 | 3-4 | 5~5.5 | 2×0.25 | 360 | 1640×1210×1322 |

| TQLZ100×100 | 100×100 | 16-20 | 5-7 | 5~5.5 | 2×0.25 | 420 | 1640×1550×1382 |

| TQLZ100×150 | 100×150 | 26-30 | 9-11 | 5~5.5 | 2×0.37 | 520 | 2170×1550×1530 |

| TQLZ100×200 | 100×200 | 35-40 | 11-13 | 5~5.5 | 2×0.37 | 540 | 2640×1550×1557 |

| TQLZ150×150 | 150×150 | 40-45 | 14-16 | 5~5.5 | 2×0.75 | 630 | 2170×2180×1600 |

| TQLZ150×200 | 150×200 | 55-60 | 20-22 | 5~5.5 | 2×0.75 | 650 | 2660×2180×1636 |

| TQLZ180×200 | 180×200 | 70-75 | 24-26 | 5~5.5 | 2×1.1 | 1000 | 2700×2480×1873 |

Packing & Delivery

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for China Factory for Industrial Maize Milling Machine - Vibro Separator – Chinatown, The product will supply to all over the world, such as: United States, UAE, Melbourne, Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!