Flour Blending Project

Brief Introduction:

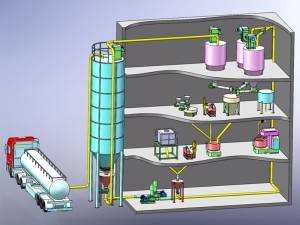

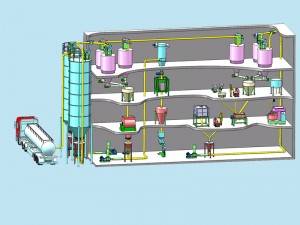

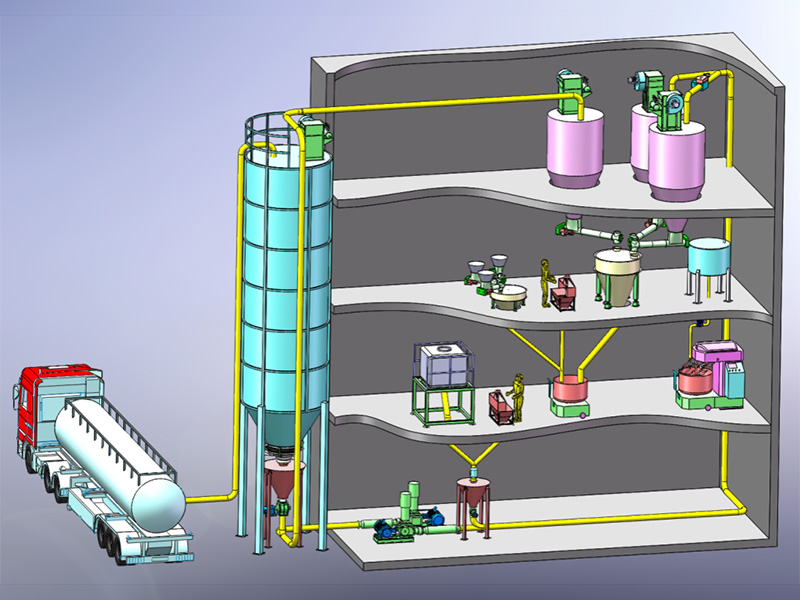

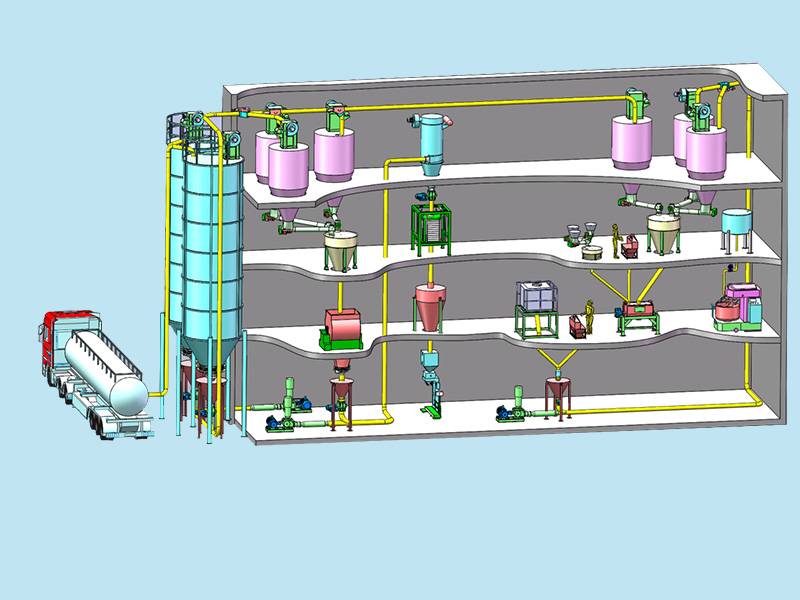

The powder blending section generally has the functions of powder blending and powder storage.

Product Detail

Product Tags

Related Video

Feedback (2)

Flour Blending Project Detail:

The powder blending section generally has the functions of powder blending and powder storage.

Powder blending:

Powder blending is the main function and purpose of the post-processing system. Powder blending is mainly in the following two aspects: first, the proportion of basic powder. As the flour production line can only produce 1-3 basic flours at the same time during production, if you want to get more different flour varieties, it can be realized through the flour blending system. The second is the blending of flour in terms of flour quality. By blending various basic powders of different qualities and adding related quality improvers, the special powder is needed by the market.

Powder storage:

Generally, the flour post-processing system has a considerable number of flour bulk storage bins, flour blending bins, and packaging bins. These flour bins can not only meet the needs of preparing various special flour but also store bulk flour.

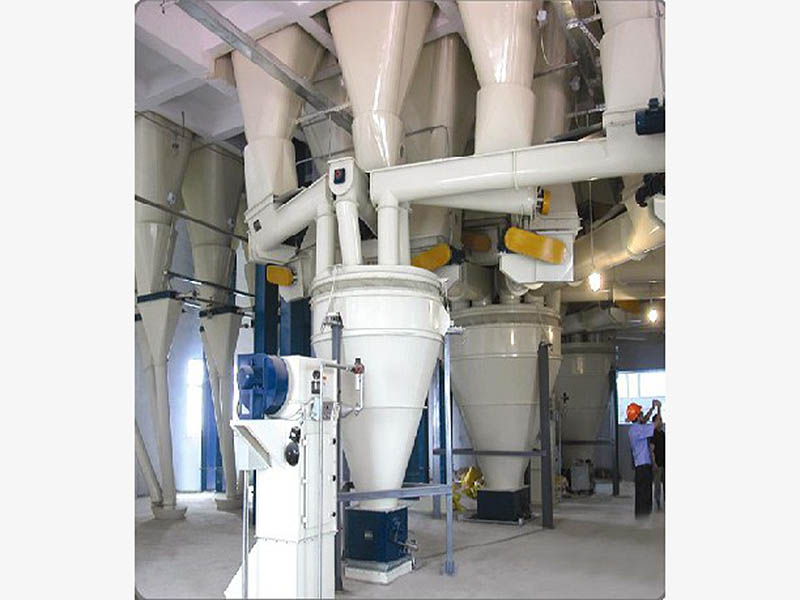

Flour Blending equipment

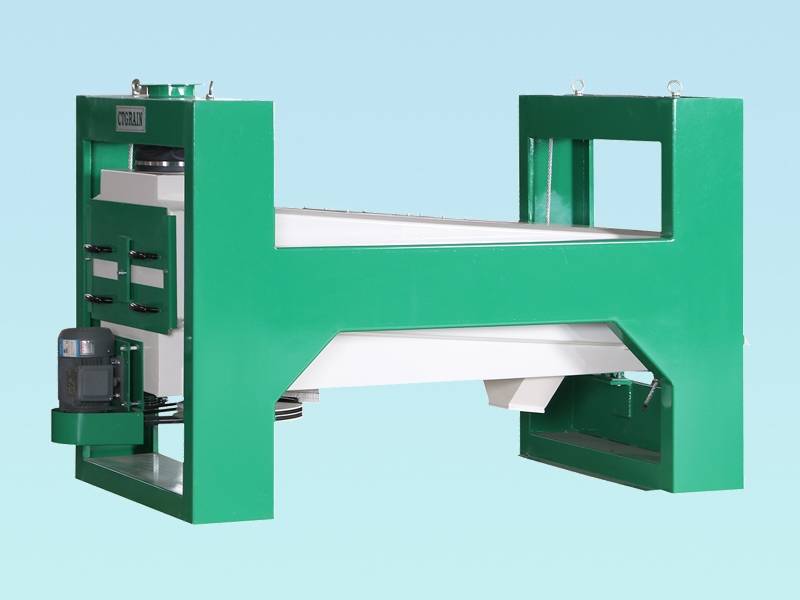

Vibro Discharger & Micro Feeder

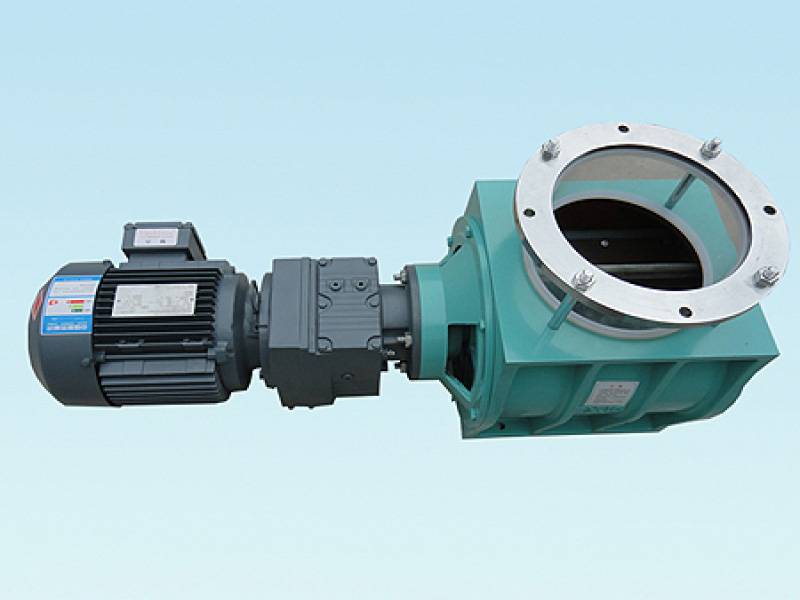

Positive Pressure Airlock & Two Way Valve

Inserted High Pressure Jet Filter & Low Pressure Jet Filter

Tubular screw conveyor & Flour Batch Scale

Application of Flour Blending(food deep processing industry)

This system includes the pneumatic conveying and storage of bulk powder, ton powder and small package powder. It adopts PLC + touch screen to realize automatic weighing and powder distribution, and water or grease can be added accordingly, which reduces labor and avoid dust pollution.

Flour Blending Cases

The Flour Blending workshop of the flour mill mixes the flour in different flour bins in proportion to ensure the stability of the final product.

The Flour Blending workshop of the flour mill mixes different types of flour in proportion to produce different types of functional flour, such as dumpling flour, noodle flour, and bun flour.

The production workshop of the noodle factory adopts an all-stainless steel powder bin and batching scale. The flour in the bulk powder bin is pneumatically conveyed to the batching scale for accurate measurement, which saves the process of manual unpacking and avoids the situation that workers add wrong amount of flour.

In the Flour Blending workshop of the noodle factory, several ingredients are added quantitatively to the flour to produce different varieties of noodles.

The Flour Blending workshop of the biscuit factory adds several ingredients to the flour quantitatively. It is made of all stainless steel and is food-grade anti-corrosion.

In the production workshop of biscuit factory, the flour would enter the dough mixer for mixing after being weighed and blended.

Packing & Delivery

>

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Flour Blending Project, The product will supply to all over the world, such as: Vancouver, Ukraine, Sydney, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.